Chiller Cabinets

Normally titled bottle cooler, these cabinets can be sourced from many different suppliers. iCool are not affiliated with any specific supplier and can offer a unit to suit your needs.

Drinks Chiller

Typically drinks chillers operate with different thermostat temperature settings. This can make these units unsuitable for food storage. The hysteresis, or temperature differential between cut in and cut out points is commonly too high for food storage, but fine for keeping your fizzy pop cold.

Bottle, or drinks coolers are most normally glass door cabinets, nevertheless, multideck and other forms can be sourced or manufactured.

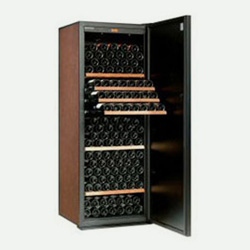

Wine Chiller

Whilst in the first instance wine chillers may resemble some of the more common drinks chiller cabinets, some of them offer humidity control to maintain the cork integrity over time. In addition they may also incorporate different storage temperatures within the same cabinet for long term bottle storage and short term cooling for serving.

Whether you need a beer fridge or back bar chiller for a bar or restaurant, or a drinks chiller for foodservice operations, or an industrial canteen, no project is too small or too large.

Wine & Beer Cellar Cooling

Whilst this term is aimed predominantly at one market, it is a simple refrigeration system operating at conditions between what is termed normal air conditioning temperatures and chill room temperatures. Typically beer cellars operate between 10 and 12C. These systems have many applications, larders, chilled work areas, etc. Beer Cellar

Off the shelf package systems are supplied by many wholesalers ready for installation and commissioning and it may prove that one of these is suited to the application specified. However, when required we can design and manufacture a system that exactly matches the customer need. This would normally entail the selection of components on their own merit including the control system and either assemble on site or at our workshop facility for site installation.

Normally cellar cooling breakdowns soar with the onset of summer. Most cooling systems are designed with hot weather in mind and the maximum throughput of the pub - but only if the equipment is working in optimum conditions.

Just like a car, if you carry out periodic maintenance on your cooling equipment, you will minimise problems.

Check your cellar cooling is working properly. It should give a cellar temperature of 10 to 12 degrees centigrade and run for a maximum of 18 hours out of every 24 hours.

Cellar cooling is designed to keep the cellar space cool. It is not designed to cool the rest of the pub! Keep doors and windows closed as much as possible.